Keekea QC inspection team ensures our chairs have the proper lumbar support and functioning backrest for comfortable seating. The team also checks on the strength, durability, and maximum load capacity of our chairs.

The durability and outer appearance of our chairs depend on the condition of plastic workpieces. Experienced workers conduct several checks and tests on each piece to ensure they meet our standards.

The dimensions of the chair and their size tolerances are in line with your engineering requirements.

The arc height and arc length must be <0.5%.

Colors should be consistent with the color plate. There should be no color differences on the surface.

The hardness should closely follow the order specification with a tolerance of only ±1°.

There should be no obvious scratches, scuffs, manufacturing heat rings, and other flaws.

Components such as nut cover and footpad must fit onto the chair easily and can be removed without difficulty.

Each part of the chair should be free of dirt, stains, and other debris.

Chairs must have the specified weight according to the design.

The hole position must have a size deviation of only ±0.5mm. The hole position deviation should only have a range of ±0.5mm.

All packaging follows your specifications such as its size and printing. Additionally, packaging must protect during transport.

The composition, appearance, and various aspect of our fabric is thoroughly checked by our dedicated QC team, ensuring all of our chairs can achieve the comfort and style you expect.

We check if the molded board meets the design requirements.

The QC team ensure the burr, hardness, color difference, and size meet the requirements.

The thickness, density, size, and surface breakage point are inspected.

The surface of the fabric should be smooth without any dents or burr.

The color is determined if it is within the specifications. Cleanliness of the fabric is checked.

We check on the structure of the fabric to ensure they are secured to the chair.

Ventilation holes are inspected, ensuring they are within the size requirements for the fabric’s breathability.

QC team ensure the correct packaging is used for the chair where the fabric has protection during delivery.

Keekea tables go through a series of tests and analyses stated below within our in-house lab. These inspections ensure our furniture meets your expected specifications on performance, safety, durability, and service life.

The shipping mark should have your corresponding model, logo, and color.

Inspection of the glass material’s cutting edge and angles are checked if it is within your specifications.

Packed tables should have no space, preventing movement during delivery.

The QC team determines if the colors are correct or if there are possible impurities within the compound before application.

The volume must be consistent with the design or your specifications.

We check for white mist, impurities, bubbles, white circles, and other irregularities on the aluminum plate.

The protective film is wrapped around the furniture to prevent scuffing or scratch damages.

We ensure the sprayed frame has a smooth quality and does not have any impurities or scratches.

For glass tops, foam boards are utilized to prevent the material from shaking during transport.

After assembling the table, we measure the length, width, and height of the whole table to determine if it is within the specified design.

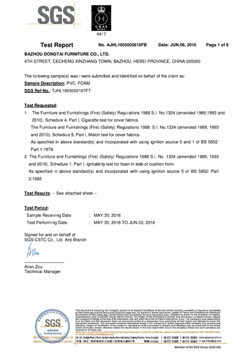

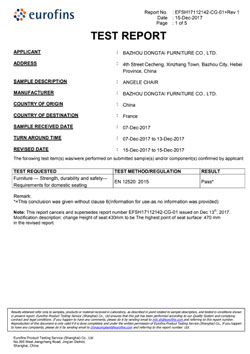

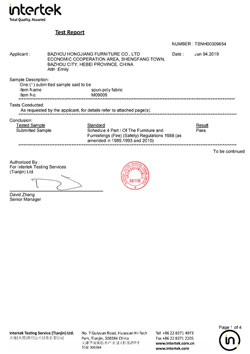

Thorough QC processes allow our tables to comply with SGS, TUV, CE, and other certifications, making them appeal to your target audience.

Get updates on sales specials and more

We want to hear from you!

Copyright © 2022, Keekea. All rights reserved.

Please provide your email address to start downloading.

WhatsApp us

WhatsApp us